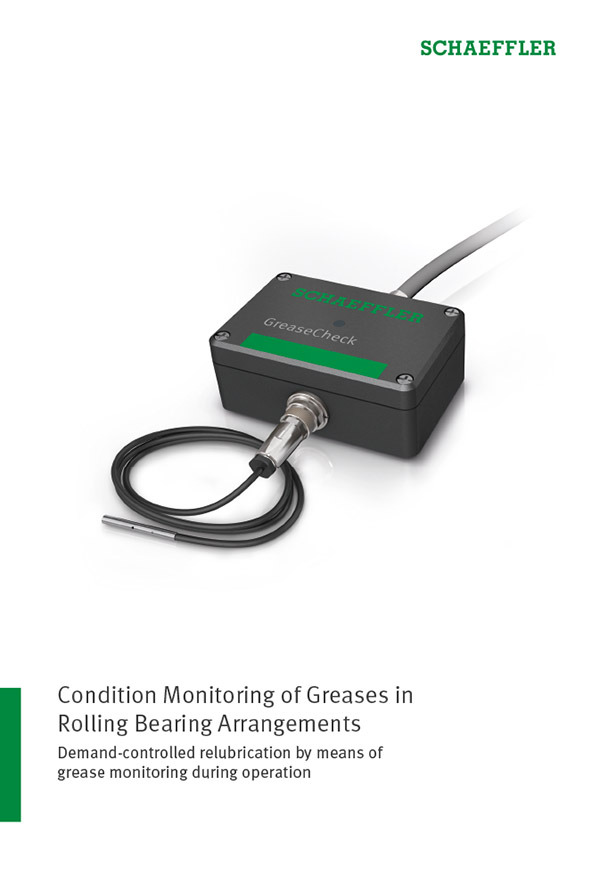

Condition Monitoring of Greases in Rolling BearingArrangements

Demand-controlled relubrication by means of grease analysis during operation

Incorrect lubrication is a major cause of bearing failure. Through correct monitoring of the grease condition, it is possible to see the point at which relubrication is required before damage occurs in the rolling bearing. With Schaeffler GreaseCheck, it is possible to see the actual requirement for relubrication based on the special electronic evaluation system. This means that grease lubrication can in future be carried out as a function of condition and not simply as a function of time.

Media category: Technical Product InformationTPI 234

Date: 2021-09-22

Order number: TPI-234-EN-GB

Publisher: Schaeffler Technologies AG & Co. KG

Pages: 34

Language: English

Other languages