Enablers for Industry 4.0: Mechatronic products

Smart sensors and mechatronic products from Schaeffler record data at the central points of any type of machine during operation. When combined with Schaeffler’s system and modeling expertise, these real-time data form the basis for a digital image of the machine that makes further analyses and digital services possible. This makes smart components from Schaeffler fundamental enablers for Industry 4.0.

Direct drives

Linear motors

Perfection – straight down the line. In a nutshell, the various Schaeffler linear motor series stand for the highest level of precision, dynamics, and energy efficiency.

Your benefit:

- High motor dynamics due to very good force to mass ratios

- Precise positioning and uniform motion thanks to zero cogging and minimal load pulsation

- Compact design

- Low wear and maintenance

- Various mounting and connection variants can be selected

Torque motors

For virtually every challenge. Are you looking for a torque motor that offers excellent advantages for your machine? Schaeffler has the expertise required to supply motors that are optimally matched to the specific application.

Your benefit:

- Efficient power generation

- Maximum power density

- High acceleration capability

- High final speeds

- Cost savings through downsizing

Positioning systems

Custom-made. High-performance. Application-optimized. Fast, precise positioning and handling systems based on direct drives ensure a better cost-benefit ratio.

Your benefit:

- High dynamics

- Shorter production cycles

- Outstanding precision

- Low wear and maintenance

- Ready-to-fit, perfectly matched components, and everything from one source

Rotary systems and sensors

TorqueSense

Torque measurement sensor system – torque sensor shaft

Relevant signals obtained at the shaft of a drive train; torque and (optionally) speed measured directly at rotating machine elements using a ready-to-fit sensor unit with a robust and non-contact measurement principle

Your benefit:

- Simple integration into the customer’s application

- No wear and long operating life

- Robust module for recording torque

- Long-term stability (no sensor drift)

SpindleSense

Innovative monitoring system for spindle bearings

SpindleSense reduces machine downtimes and increases the utilization of machine capacity.

Your benefit:

- Electronic protection against continuous overload and collision damage

- Sensor ring monitors displacement of the spindle bearing with micrometer precision

- Combination of displacement measurements and Schaeffler’s rolling bearing expertise allows operating conditions to be assessed

- Detection of critical operating conditions within 2 milliseconds

YRTCMA/YRTSMA measuring system bearings

Measuring system bearings with MHA measuring heads for absolute, inductive angle measurement

Robust and functional safety compliant measuring system for excellent machining quality, maximum machine availability with an ideal form factor for electrically driven axes in machine tools

Your benefit:

- Excellent positioning accuracy and extremely small positioning scatter band

- High machine availability

- Very short initial operation times

- A reference search is not required

- Lower installation space requirements

- Free space in center of machine

- Functional safety compliant measuring systems for safety-relevant, electrically driven axes

- No additional components for the measuring system

YRTCMI measuring system bearings

Measuring system bearings with MHI measuring heads for incremental, inductive angle measurement

Robust and functional safety compliant measuring system for excellent machining quality, maximum machine availability for electrically driven axes in machine tools

Your benefit:

- Excellent positioning accuracy and extremely small positioning scatter band

- Optimal positioned incremental angle measuring system

- High machine availability

- Easy assembly and adjustment

- Lots of engineering options

- Functional safety compliant measuring systems for safety-relevant, electrically driven axes

- No additional components for the measuring system

- Compatible with all relevant control systems

- Stable data transmission by using slip rings

YRTCM/YRTSM measuring system bearings

Measuring system bearings with SRM electronic measuring system for incremental, magneto-resistive angle measurement

Excellent machining quality, increased machine availability with an ideal form factor for electrically driven axes in machine tools

Your benefit:

- Excellent positioning accuracy and high machining quality

- High machine availability

- Very short initial operation times

- Lower installation space requirements

- Free space in center of machine

Linear systems and sensors

DuraSense

Monorail guidance systems with Schaeffler DuraSense regulate their own lubricant requirements.

A sensor on the guide carriage transmits the data to the electronic evaluation system, which records the current lubricating conditions and initiates automatic relubrication if required.

Your benefit

- Consistently optimum lubrication conditions in the linear guidance system

- Increased operating life of the linear guidance system and thus the entire machine

- Increased machine availability due to reduced number of machine downtimes

- Lubricant requirement reduced by up to 30 %

- Maintenance and subsequent costs reduced through planned maintenance

P.ACT linear actuators

Electromechanical piston actuator

The linear actuators can be used in a wide variety of industrial applications – as a force actuator or as a positioning system, depending on requirements.

Your benefit:

- Small design envelope for higher axial forces and thus a higher power density

- Designed for long operating durations

- Replaces conventional hydraulic and pneumatic systems

- Flexible fixing options along the entire actuator length

- Energy-efficient

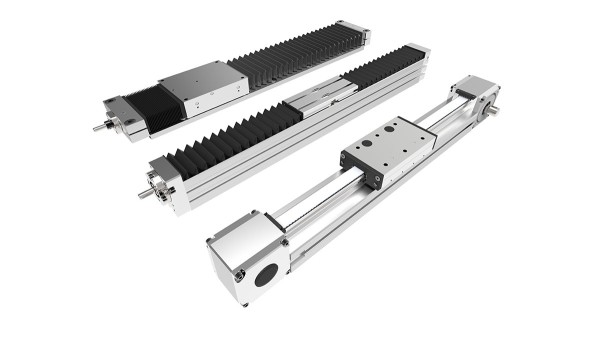

Driven linear units

Single-axis or multi-axis complete systems for combination with the suitable application technology

Optionally with a specifically matched control unit from a complete modular system

Your benefit:

- Ready-to-fit solution

- Simple system integration

- Access to Schaeffler’s product specialists from development through to manufacturing technology

- Support of high torques around the traverse axis possible, particularly for the tandem series

- Very fast cycle times possible -> Vmax = 10 m/s

Consultation and contact

Gather valuable data for your application and contact us.