The Advantages of Digitalization for OEMs and Railway Operators

As a component supplier to the railway sector, Schaeffler makes a sustained contribution to improving the competitive edge of the railway sector with respect to other modes of transport. We are therefore investing heavily in digitalization and thus optimizing the entire supply chain.

We consider ourselves to be a partner to our customers. We can utilize our specific knowledge of standardized product identification by means of DMC very effectively in the “railway system”.

Advantages of digitalization

Optimize maintenance costs and increase the reliability of rail vehicles

The digitalization of the supply chain by means of DMCs to the GS1 standard offers outstanding potential with regard to the traceability from the manufacturer to the operator, the electronic exchange of data, and the development of new service models.

Using an axlebox bearing as an example, this video shows how the digital twin is created for Schaeffler’s railway products and how the marking of bearing components with a unique data matrix code lays the foundation for the development of a digital supply chain.

If component manufacturers, vehicle manufacturers, and operators agree to a standardized exchange of data, the information that is gained can significantly help to optimize maintenance costs and increase the reliability of rail vehicles.

Digital twin – link to DMC

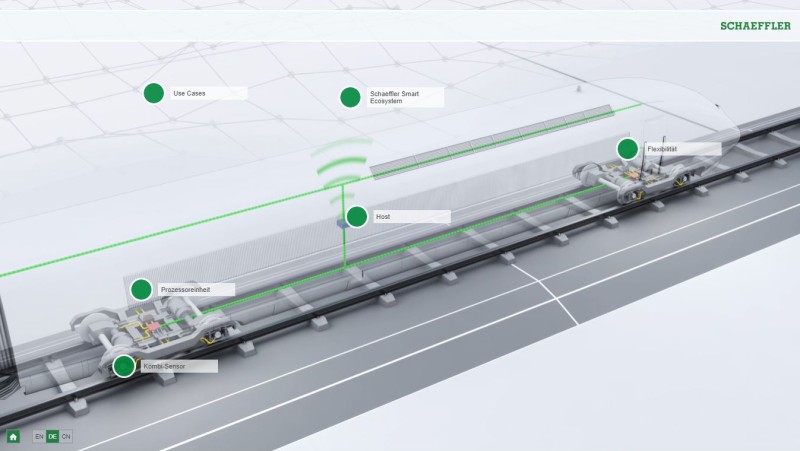

The option of a clear and unique product identification by means of DMC creates the prerequisites for generating a digital twin for Schaeffler’s railway products. In addition to digitization within the production and process landscape, this will also open up the possibility of integration in our Smart EcoSystem.

The Schaeffler Smart EcoSystem is a flexible, scalable, and holistic business model for Industry 4.0. It combines Schaeffler's engineering expertise with algorithm-based data modeling and offers open interfaces for internal and external cloud-to-cloud solutions. Data obtained from the operation of our products can also be taken into account as well as the data from on-board systems installed by the customer. The focus throughout this process remains on the customer and their application.

What is the use of a Data Matrix Code on railway bearings?

Labeling bearing components with a unique Data Matrix Code (DMC) is the foundation for the development of a digital supply chain. Therefore, the DMC is the basis for the digitalization.

Find out more about how Schaeffler uses the DMC in their processes and how your business can benefit from using the DMC technology.

Schaeffler’s 100% return models

Reliable rail traffic combined with longer maintenance intervals requires more intelligent maintenance concepts. We at Schaeffler already offer our customers two different maintenance models for the reconditioning of axlebox bearings. These enable you to maintain your fleet quickly and predictably while saving costs and time for the storage of replacement bearings.

If you also opt for the data matrix code marking, you will ensure that your trains are back on the rails as quickly as possible and can also track the entire exchange process.

Watching this video you will learn in only 3 minutes which of the two maintenance models is the right one for you.

Reconditioning of bearings

Safety and reliability are indespensible in the railway sector. In many cases, it is more economical to recondition used rolling bearings rather than use new bearings, and the delivery times are usually shorter.

This video explains Schaeffler’s professional and economical bearing reconditioning service and opens up opportunities to start digitizing your existing fleet today.

Interactive Animation

- Use Cases

- Processing Unit

- Combined Sensor

- Schaeffler Smart Ecosystem

- Host

- Flexibility

Story: Staying on Track

Flexible maintenance intervals can increase productivity in rail traffic. Schaeffler provides the technology required for this.

Contact

Would you like to discuss a specific project with us or obtain more information about our sector-specific solutions?

Feel free to contact us – one of our experts will be in touch with you as soon as possible.