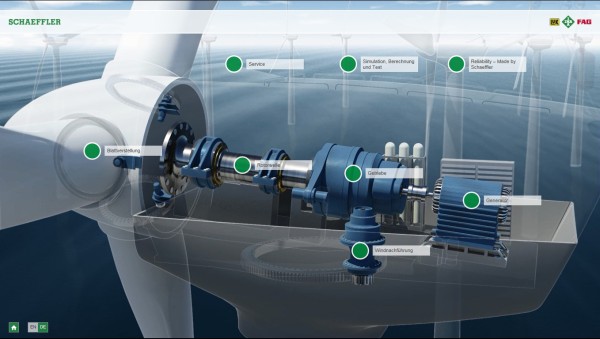

Gearbox

The Right Bearing Support for Every Gearbox

Increasing megawatt ratings require larger and higher capacity gearboxes. The operating conditions for rolling bearings in wind turbine gearboxes cannot be compared with those for industrial gearboxes.

Challenges for the bearing support- Highly-dynamic forces with extreme maximum and minimum loads

- Sudden changes in load

- Varying operating temperatures

- Deformation of gearbox housing

- Bearings with high static safety

- Reliable dynamic dimensioning according to international design standards

The Largest and Most Valuable Bearings in a Wind Turbine Gearbox

Planet carrier bearings are the largest and therefore most valuable bearings in a wind turbine gearbox. The loads they have to support depend on the main bearing concept selected. These bearings are usually subjected to relatively low loads due to their size.

Full complement INA X-life cylindrical roller bearing

Advantages

- High load carrying capacity

- Long life

- High operational safety

- High axial load carrying capacity and reduced friction due to optimized rib contact

- Improved run-in behavior

- Increased protection against White Etching Cracks (WEC)

- Increased guidance accuracy due to limited tolerances

Features

- Optimized rib contact

- Durotect B coating

- X-life quality

FAG tapered roller bearing

Advantages

- Precise guidance of the gear teeth

- Internal clearance can be precisely set

- No additional axial bearing necessary

- High axial forces can be accommodated by the large contact angle

- Improved run-in behavior

- Increased protection against White Etching Cracks (WEC)

Features

- Adjusted bearing arrangement

- Durotect B coating

High Loads within a Small Design Envelope

Planet gear bearing supports are extremely challenging bearing positions because of the high radial loads that occur. Only a limited amount of space is available for this bearing support, and the planet gears, which have comparably thin walls, tend to distort leading to unintentional rotation of the bearing outer ring in the planet gear.

FAG cylindrical roller bearing (direct bearing support)

Advantages

- High load carrying capacity

- Long service life

- High operational safety

- Cost-effective design with low radial section height

- No outer ring creeping

- Improved run-in behavior

- Increased protection against White Etching Cracks (WEC)

- Optimum load distribution on the bearings

Features

- Cylindrical roller bearing without outer ring

- Raceway is integrated in the planet gear carrier

- Limited internal clearance

- Durotect B coating

- X-life quality

FAG X-life high-capacity cylindrical roller bearing (direct bearing support)

Advantages

- Low friction

- Higher load rating due to optimized use of the design envelope

- High stability

- Lightweight design

- Optimized lubricant flow

- Improved run-in behavior due to Durotect B

- High resistance to white etching cracks due to Durotect B

Features

- Streamlined cage design

- Cylindrical roller bearing without outer ring

- Raceway is integrated in the planet gear carrier

- Durotect B coating

- X-life quality

Streamlined cage design

The high-capacity cylindrical roller bearing combines the advantages of both full complement bearings and cage type bearings due to the new streamlined cage design.

Downsizing possible

When fitted as a direct bearing support, the FAG high-capacity cylindrical roller bearing in X-life quality allows significantly improved use of the design envelope compared to a comparable standard bearing support.

- Standard bearing

- FAG high-capacity cylindrical roller bearing

→ 45 % less weight for the planet gear with the same bearing life

FAG High Capacity Cylindrical Roller Bearing in X-life Quality

Planet gear bearing for wind turbine gearboxes

Proven Locating/Non-locating Bearing Solutions

Bearing supports for hollow shafts support high radial loads as well as high axial loads in the case of planetary gears with helical gear teeth. Combinations of locating/non-locating bearing arrangements with two tapered roller bearings and one cylindrical roller bearing or two cylindrical roller bearings with one four point contact bearing with radial release have proven themselves in this application.

FAG cylindrical roller bearing

Advantages

- Effective support of radial loads

- High operational safety

- Easy assembly due to separability

- Low bearing friction

- Suitability for high speeds

- Improved run-in behavior

- Increased protection against White Etching Cracks (WEC)

- Non-locating bearing function within the bearing is possible

Features

- Non-locating bearing

- Separable

- Durotect B coating

- X-life quality

FAG four point contact bearing

Advantages

- Effective support of axial loads

- Favorable kinematics under axial loads in both directions

- Suitable for high speeds

- Low lubricant requirement

- Increased protection against White Etching Cracks (WEC)

Features

- Effective support of axial loads

- Retaining slot in the outer ring for secure location

- Durotect B coating

High Rotational Speed

Intermediate shafts are used in single-stage planetary gearboxes in particular. A comparably small amount of space is available for the bearing support for the high radial loads and moderate axial loads that occur here. The output shaft rotates at high speeds.

Double-row FAG tapered roller bearing

Advantages

- Long service life

- High operational safety and short mounting time due to preset internal clearance

- Effective support of radial and axial loads

- Compact bearing design

- Increased protection against White Etching Cracks (WEC)

Features

- Locating bearing

- Durotect B coating

FAG cylindrical roller bearing

Advantages

- Effective support of radial loads

- High operational safety

- Easy assembly due to separability

- Low bearing friction

- Suitability for high speeds

- Improved run-in behavior

- Increased protection against White Etching Cracks (WEC)

- Non-locating bearing function within the bearing is possible

Features

- Non-locating bearing

- Separable

- Durotect B coating

- X-life quality

Proven Gearbox Bearings

With its preferred series, Schaeffler offers a selection of gearbox bearings that have proven themselves in wind turbine gearboxes.

Advantages

- Products that have already been validated

- Faster development processes

- Improved availability

- Customers can make a preselection