Schaeffler Expands OPTIME Portfolio: FAG OPTIME E-CM Monitors Electrically Driven Units

2026-01-27 | Herzogenaurach

- Electrical condition monitoring of three-phase motors with FAG OPTIME E-CM

- More comprehensive insight into the condition of production systems

- Easy installation and AI-supported data evaluation

The Schaeffler OPTIME ecosystem is a leading solution for condition monitoring and smart lubrication of machinery. Sensor technology and software combined with the expertise of a globally leading bearing manufacturer characterize this offering from the Motion Technology company.

With the FAG OPTIME E-CM (Electrical Condition Monitoring, E-CM), Schaeffler is now expanding its portfolio to include electrical condition monitoring of three-phase motors – such as those commonly used in compressors, rotary pumps, fans, blowers, grinding machines, and in large quantities in all industrial sectors. Schaeffler is thus taking the next step towards trouble-free production processes.

Additional perspective for condition monitoring

"Electrical condition monitoring adds an essential perspective to the existing OPTIME ecosystem and enables maintenance teams to detect both mechanical and electrical malfunctions at an early stage," says Dr. Philipp Jussen, Head of Schaeffler Industrial Lifetime Solutions Europe.

The existing OPTIME sensors are specialized in detecting vibrations that indicate premature wear and possible mechanical malfunctions. FAG OPTIME E-CM rounds off the product family by monitoring and evaluating electrical currents and voltage of the electrical drive. "As a result, our customers can now prevent unplanned downtimes in production environments even better", explains Dr. Philipp Jussen.

For example, FAG OPTIME E-CM enables early detection of insulation faults and damage, cable defects, static and dynamic eccentricity, broken rotor bars, voltage fluctuations, and overcurrents. Customers benefit from improved system transparency, resulting in higher plant availability, proactive maintenance planning, and thus lower costs and personnel expenditure. This is especially true for systems that work in hard-to-reach environments, as the sensors are attached to the cables in the control cabinet.

Easy Installation – AI-Supported Data Analysis in the Schaeffler Cloud

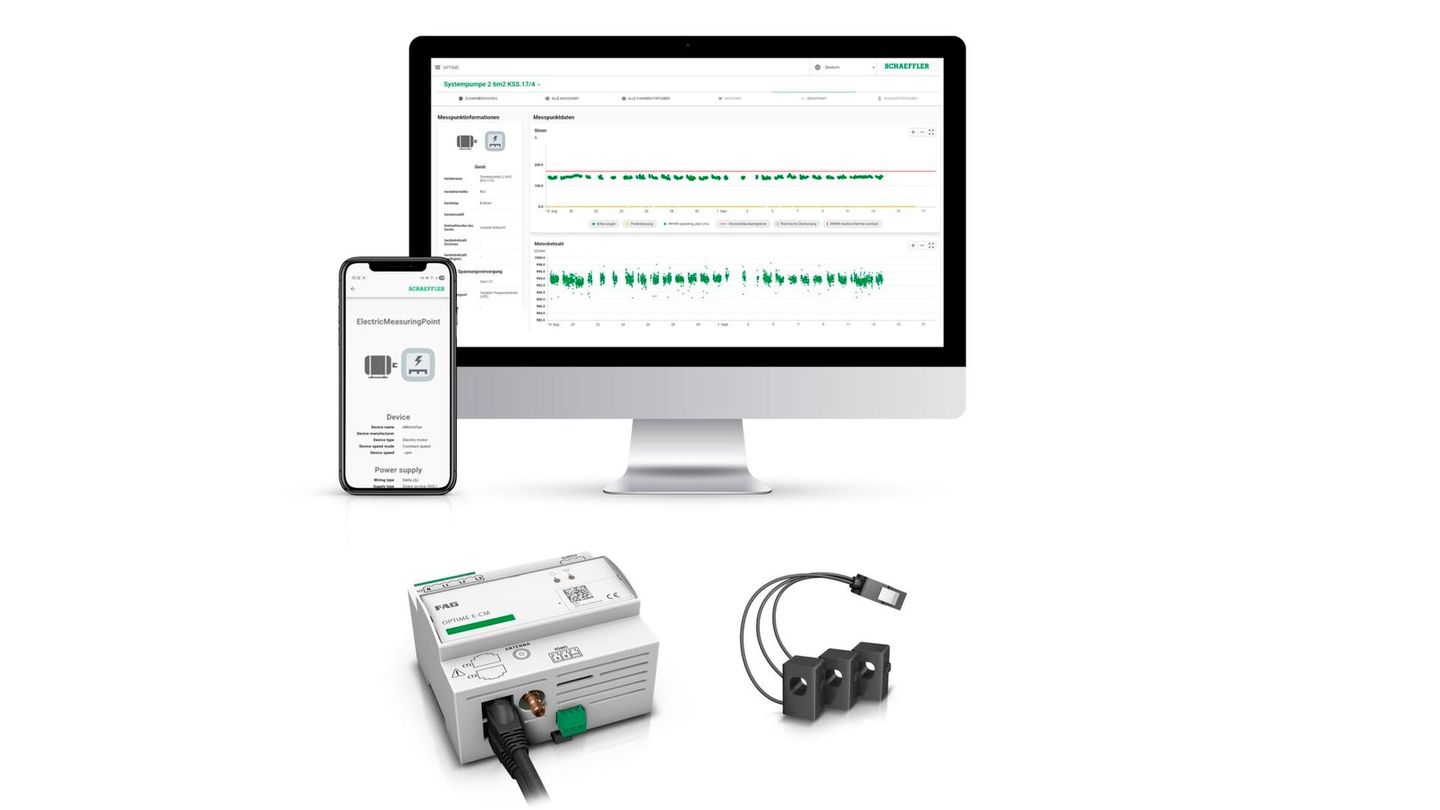

The technical installation is straightforward for electrical personnel. The system consists of a measuring unit and the sensors for current detection, which are attached to the live cables of the generators in question. Both are located in the control cabinets that are easily accessible for maintenance staff.

Either current transformers (split-core) or Rogowski coils (wound coils that are placed around a conductor and record the temporal change of a current flow) may be used as sensors. The distance between the sensor and the measuring unit in the control cabinet can be up to ten meters and is bridged by cable. Additionally, the three-phase voltage signals of the electrical motor are connected to the main unit.

The measuring unit sends the data obtained by FAG OPTIME E-CM directly and wirelessly via a protected LTE data connection to the Schaeffler Cloud for analysis. In addition to its decades of experience as a manufacturer and developer of rolling bearings, Schaeffler uses modern machine learning technologies and artificial intelligence to find patterns in the data and derive recommendations for maintenance teams.

Standalone installation or integration into existing OPTIME ecosystem

Maintenance managers receive notifications via their dashboards on the PC or via app when irregularities occur. In addition, the collected data can be used to document and improve existing processes. FAG OPTIME E-CM can be integrated into an existing system or set up as the first OPTIME solution.

With the now even more comprehensive OPTIME ecosystem, complex production environments with many different units can be monitored and maintained easily, efficiently, cost-effectively and reliably. FAG OPTIME E-CM is launching end of February 2026 in Europe and some Asian countries and will gradually be available globally.

More information on the FAG OPTIME E-CM: medias.

Publisher: Schaeffler

Country: Germany

Terms of use for Schaeffler press pictures

Schaeffler press pictures may only be used for editorial purposes. Unless otherwise stated, all copyrights and rights of use and exploitation are owned by Schaeffler Technologies AG & Co. KG, Herzogenaurach (Germany) or by one of its affiliated companies. The reproduction and publication of Schaeffler press pictures is only permitted if the source is stated as follows: "Image: Schaeffler". The pictures may be used free of charge in such cases. The use of pictures for advertising or other commercial purposes, in particular their disclosure to third parties for commercial purposes, is hereby prohibited. Pictures may only be edited with the approval of Schaeffler.

We kindly request that a specimen copy be sent to us when Schaeffler press pictures are published in printed media (or a digital copy in the case of publication in electronic media). When using Schaeffler press pictures in films, please notify us and state the title of the film.

Use and utilization of Schaeffler press pictures is subject to the substantive laws of Germany without its conflict of law provisions. The place of competent jurisdiction shall be Nuremberg, Germany.

Postal address:

Schaeffler Technologies AG & Co. KG

Corporate Communication

Industriestrasse 1-3

91074 Herzogenaurach

Germany

Press releases

Package (Press release + media)