Pure efficiency with the EMR4 electric axle drive

Quiet, efficient, and powerful: Schaeffler’s EMR4 electric axle drive platform (Electronics, Motor, Reducer) represents state-of-the-art drive technology – already in use today in award-winning vehicles worldwide. Compared with the previous generation, the platform delivers up to 6% higher efficiency. And crucially, in today’s highly dynamic market, flexible power scaling enables integration into a wide range of vehicle architectures at an attractive cost.

Modular by design: electric axle drive EMR4 for greater individuality

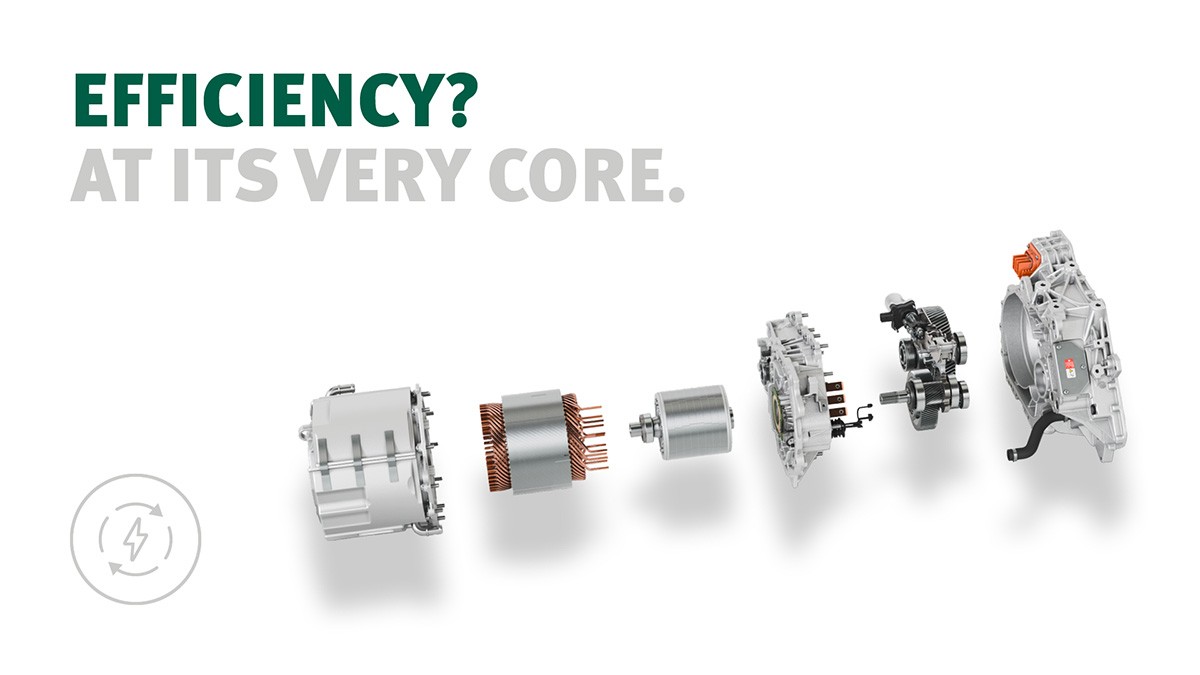

The modular architecture of the EMR4 electric axle drive allows precise adaptation to a wide variety of vehicle concepts:

- Different inverter, reduction gearbox, rotor/stator, and housing variants provide tailored solutions for diverse power and packaging requirements.

- Standardized interfaces ensure maximum compatibility and simplify integration into existing vehicle architectures.

- Built on a modular system principle, the platform can be freely configured to enable customized solutions.

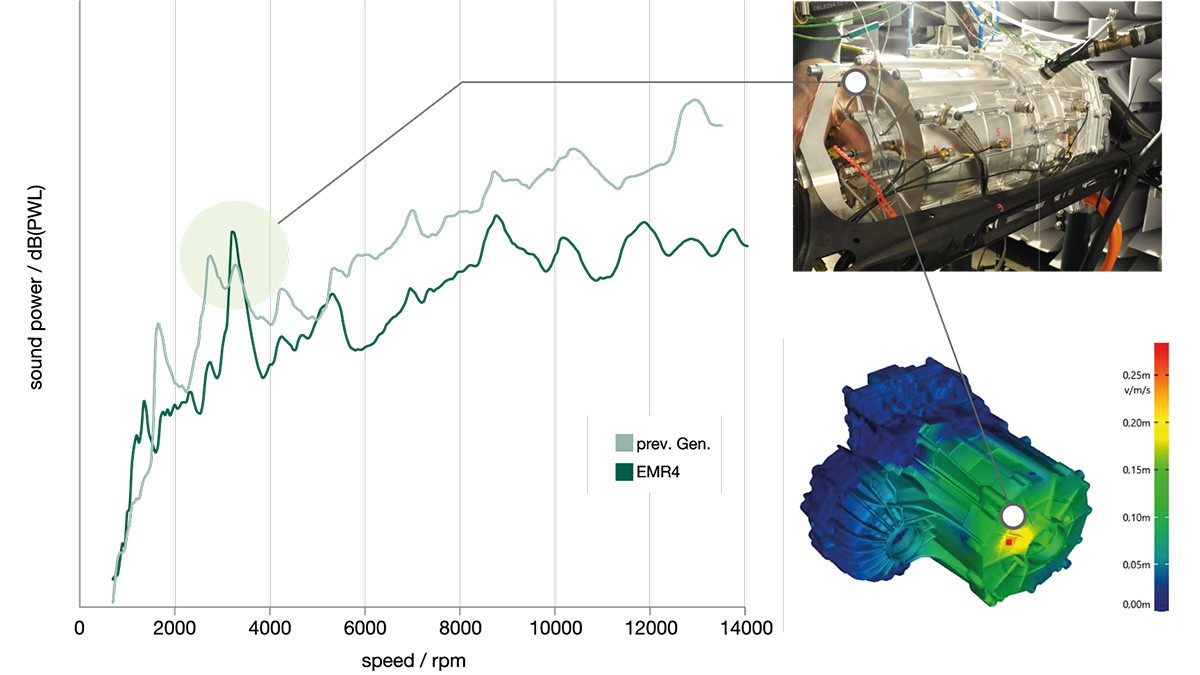

Optimized NVH (Noise, Vibration, Harshness) characteristics provide a refined experience. Targeted simulations and testing minimize both structure-borne and airborne noise. High-precision manufacturing techniques reduce vibrations and noise to an absolute minimum, ensuring a smooth, comfortable ride for drivers and passengers alike.

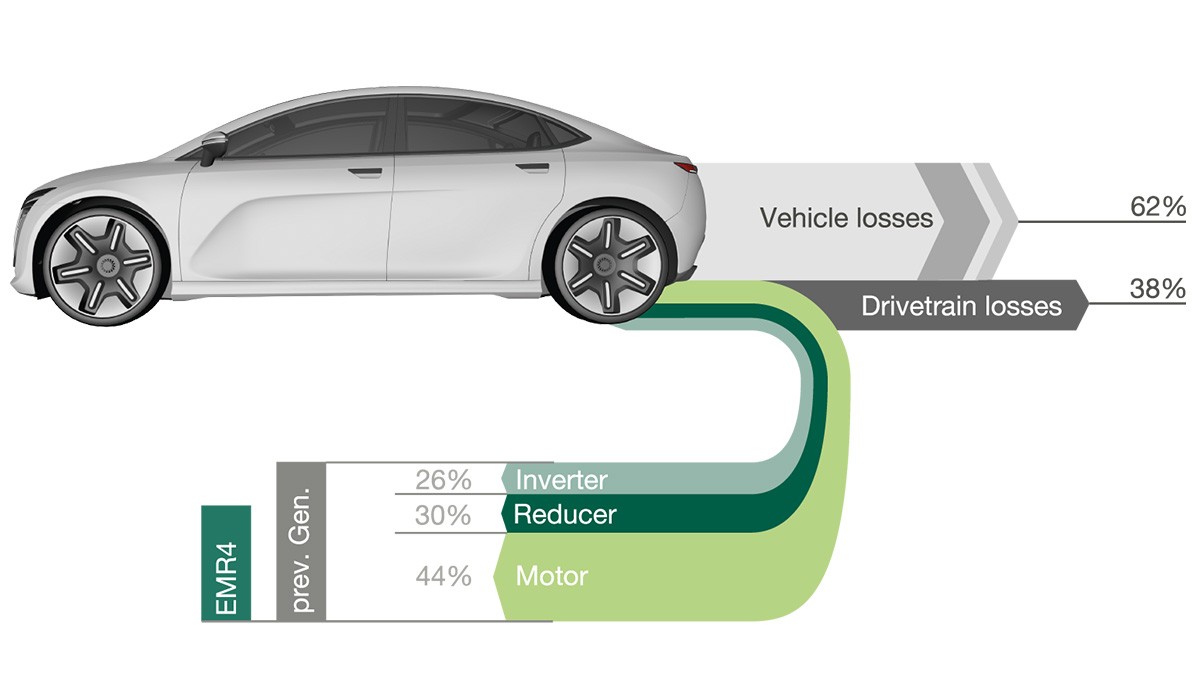

Every detail of the electric axle drive is engineered for maximum performance, delivering efficiency that sets it apart. Compared to the previous generation, the EMR4 improves energy efficiency by up to 6%, increasing range, lowering operating costs, and supporting OEMs in achieving their sustainability goals. This advancement is made possible by optimized power electronics, a highly efficient motor, and an enhanced gearbox.

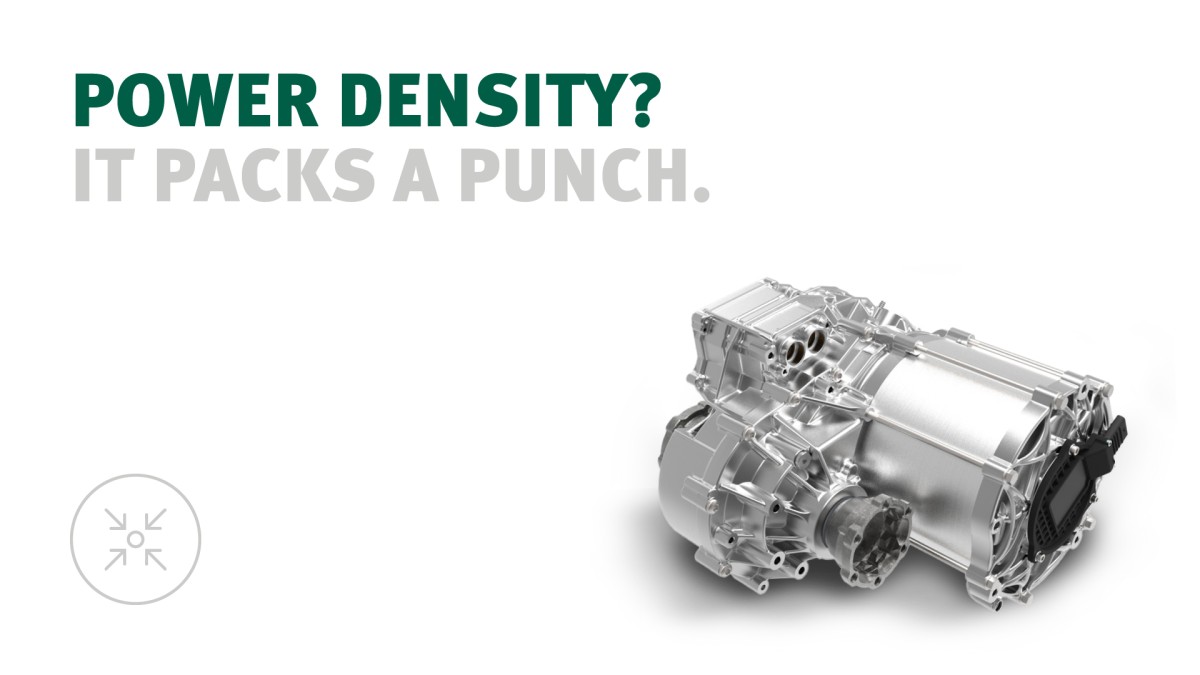

Compact yet powerful, the EMR4 sets new benchmarks for power density. Its scalable architecture ensures top-level performance across applications. Depending on the configuration, the newly developed EMR4 axle drive delivers between 80 kW and 230 kW of power, with axle torque ranging from 1,700 Nm to 4,000 Nm. The scalability achieved is also clearly reflected in the module’s weight: Depending on the required drive power, the mass ranges from just 45 kg to around 80 kg.

Are you interested in the EMR4 platform? Get in touch

The EMR4 platform combines technological excellence with industrial maturity, tailored to meet your specific needs. Want to learn more or take the first step into the future?