Sustainable concept reduces emissions and saves costs

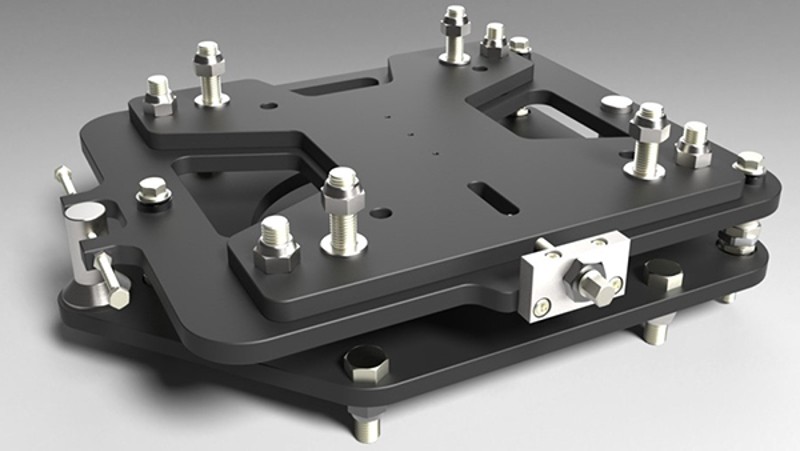

One of the most renowned German car producer is breaking new ground in the ventilation of its production facilities. The continuous monitoring of key system parts was just one element of the planning process, as a sustainable reduction in emissions also played a major role. The holistic concept for the system was provided by Altmann Industrietechnik, a technology partner certified by Schaeffler. The solution was based on Schaeffler components and a patented 3D motor slide.

Benefits

- Reduced friction losses - as a result of converting from V-belt to toothed belt drives

- Improved signal analysis and visualization in premium quality

- Less maintenance work and extended system life

- Reduced CO2 emissions

- Reduced total cost of ownership

- More time available for core tasks

Contact us about the Industry 4.0 solution.

Would you also like to use the cross-industry Industry 4.0 solution in your plant?

At a glance

Do not miss any news and subscribe to our free of charge newsletter.