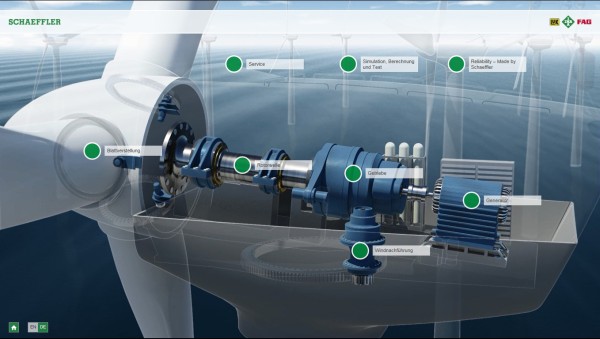

Generator

High Vibration Loads

Generators in wind turbines are subject to high vibration loads. This additional permanent load has a negative influence on the cages and places strain on the lubricant.

- High speeds

- High temperatures

- High vibration loads

- Risk of the passage of current

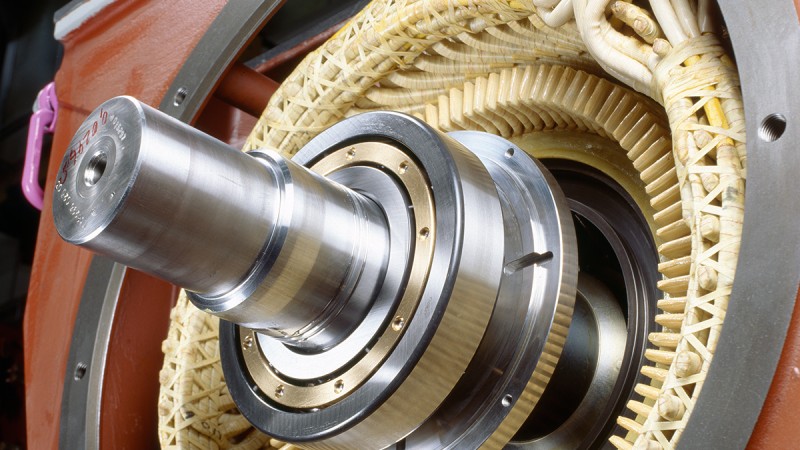

Prevention of Damage due to Current Passage

Animation: Bearing damage due to the passage of current

Damage due to the passage of electrical current

Current passage causes serious bearing damage and thus leads to premature, unexpected failure of a motor or generator:

- Craters caused by melting

- Molten droplets

- False brinelling

- Discoloration

- Micro-wear

- Premature aging of the lubricant

- Noticeable noise behavior

Animation: Longer operating life due to current insulation

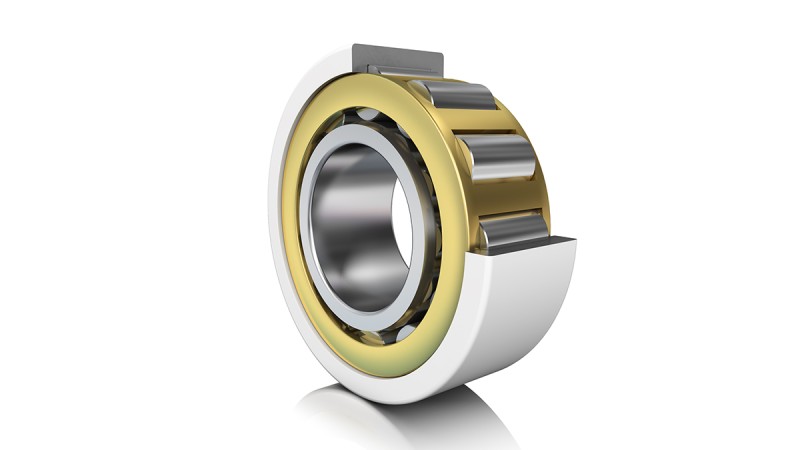

Longer operating life due to current insulation

Current-insulating bearings prevent damage due to the passage of electrical current and thus ensure lower maintenance costs and higher machine availability.

All current-insulating bearings have the same dimensions and load carrying capacities as those without insulation, which makes them perfectly interchangeable.

INSUTECT A

Advantages

- Highly wear-resistant insulating layer

- Breakdown voltage up to 5,000 volts DC

- Also suitable for damp environments

- Good conductor of heat

- Interchangeable with standard bearings

Features

- Aluminum oxide ceramic layer

- Different coating types are available for optimum functional performance

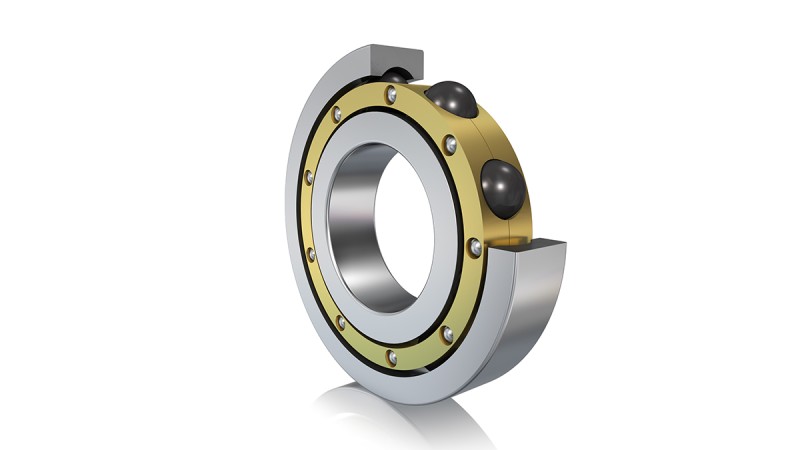

Hybrid Bearings

Advantages

- Maximum protection against passage of electrical current

- Low wear in the rolling contact

- Longer bearing and grease operating life

- Suitable for high speeds

- Good emergency running characteristics

- Rolling elements are resistant to chemicals

- Interchangeable with standard bearings

Features

- Hybrid bearing

- Ceramic rolling elements

- Same dimensions as standard bearings